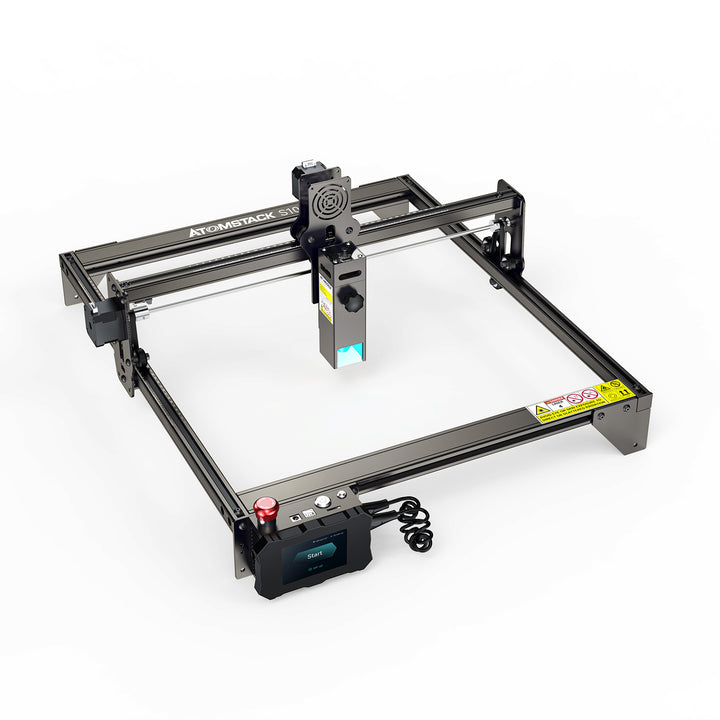

atom stack

laser engraver

10 Laser Engraved Gift Ideas

Christmas is just around the corner and many of us are racking our brains to create the perfect laser engraved gift for that special someone. If you're like most people, you probably have a lot of people on your Christmas shopping list ready to shop.

Laser engraving opens up a whole new world of possible personalized holiday gift ideas. With personalized engraving, you can turn the simplest gift or idea into something personal, unique and truly special.

Most importantly, you know exactly what you're getting for the guy who has it all or nothing. Laser engraved gifts are not just a gift, they are a work of art and a keepsake that the recipient can keep forever and always remember who they got it from.

If you own a laser cutter for the holidays, you're like an elf in Santa's workshop creating all kinds of personalized gifts for everyone you love, right?

For inspiration this holiday season, here are our 10 laser engraved gift ideas for your special someone:

1. Engraved Gold Pendant

Engraved jewelry is a timeless and emotional gift. Whether it's an inspirational quote or an anniversary, engraveable necklaces, rings and bracelets will always be with you.

Add a personal touch to a special jewelry gift for that special someone. Celebrate life's personal moments and capture messages from the past with a piece of classic yet contemporary jewelry.

Engrave your favorite spell, your favorite name, or the initials of your loved ones on these keepsake jewelry. Carefully crafted custom items lead every modern person through the ever-changing era in a stylish way.

2. Personalized carved wooden cutting board

If someone in your family loves to cook and enjoys spending time in the kitchen, a custom cutting board (or other kitchen gadget) is a great way to add more fun. One of his favorite hobbies. Especially during Christmas time.

Wooden cutting boards can easily be engraved with the recipient's name, special holiday wishes, quotes from a favorite poem or culinary theme, shared recipes, or pictures of the recipient's favorite food. There's no limit to creativity with this project - the wooden cutting board is essentially a blank canvas for laser engraving.

3. Solid wood laser engraved individual coasters

Any of these solid wood coasters would make a great conversation starter or gift for a friend or loved one, or even a great piece of art to put on the table with the family this holiday season.

A beautiful set of wooden coasters carefully engraved with the name, date or text of your choice. This special gift can remind your family and friends of special events in their lives. They're also perfect for weddings, housewarmings, anniversaries, or any special occasion that calls for a personal and creative style sure to delight the recipient!

These coasters are handmade functional home art because these coasters not only save table surface, but also are super holiday decoration.

4. Laser cutting and engraving beverage name tags

Imagine your guests' reactions when they see their names on these personalized wooden beverage place cards! It's the perfect way to wow your guests this holiday season. You have the option to adjust the shape, font, size and style to perfectly fit your wedding.

Your laser cut and engraved wooden beverage place cards will be the highlight of a dazzling show. They are made of solid wood. creative! Use them as add-on cards, place cards or just for sharing messages.

5. Personalized Laser Engraved Tableware

All we want to do this holiday season is go home and see our family, friends and everyone we love again.

However, the wait time on the luggage carousel can be one of the most heartbreaking, sweaty, annoying times of the entire travel experience. Even the most seasoned traveler would be intimidated if he didn't see his luggage slide off the conveyor belt.

As with most aspects of travel, the best planning is planning. Secure and Unique Luggage Tag By personalizing the luggage tag ID card with laser cut and engraved information, it will help you identify it easily as it will stand out from the crowd and of course help you return your lost luggage bring home.

7. Personalized Laser Engraved Wine Glasses/Mugs

These personalized wine glasses are the perfect gift for the upcoming holidays, or even for any occasion. Personalize it with your name and logo!

Personalized wine glasses are ideal if you're looking for the "perfect" gift for a discerning recipient who seems to have it all, or if you're looking for a personal gift for a holiday occasion. Pair them with your loved one's favorite wine and you'll always be known as the best gift giver in town.

Surprise the wine lover in your life and a great way to celebrate a memorable moment.

8.UV printing jewelry

3D printed jewelry is on the rise right now, and there's nothing stopping you from taking full advantage of 3D technology. Traditional jewelry making is a meticulous and time-consuming process.

It’s important to note that when we talk about 3D jewelry printing, we’re not talking about printing jewelry directly from precious metals. While it's definitely possible, and the technology is advancing rapidly, most jewelers won't use a 3D printer in this way, as the technology isn't exactly affordable.

Interestingly, 3D printed jewelry is really cheap in the market. Get inspired by 3D printed bracelets and other decorative elements and see what you can achieve with them.

Best of all, these UV printed jewelry can be a one-of-a-kind gift this holiday season as they keep coming up with new and truly inspiring results.

9.UV printing picture wall

There's nothing like hanging a beautiful piece of light art in your beautiful home, especially during this Christmas season when everyone comes together to celebrate.

Just when you thought art could only have so much to offer to those of us who love art but don't have extraordinary talent, you discover something new. This doesn't just apply to one medium or genre, but many.

No assembly required, just hang it on the wall to change the vibe of your home. "Printing is performance", then UV seems to have opened up a series of new play scenarios for photography. All that remains is to determine how long the execution will last.

10. Laser Engraved Dog Tags

Unfortunately, your pet will probably run away at least once in his life.

This happens to everyone. No matter how careful we are or how secure our garden fence is, at some point our dogs will try to escape. Sooner or later they will. We don't want that.

Save the heartache by adding a custom and fitting pet tag for your pet. Your mind will thank you later. Laser engraved pet tags are also a perfect gift for our loved ones who also love their pets.

0 Comments

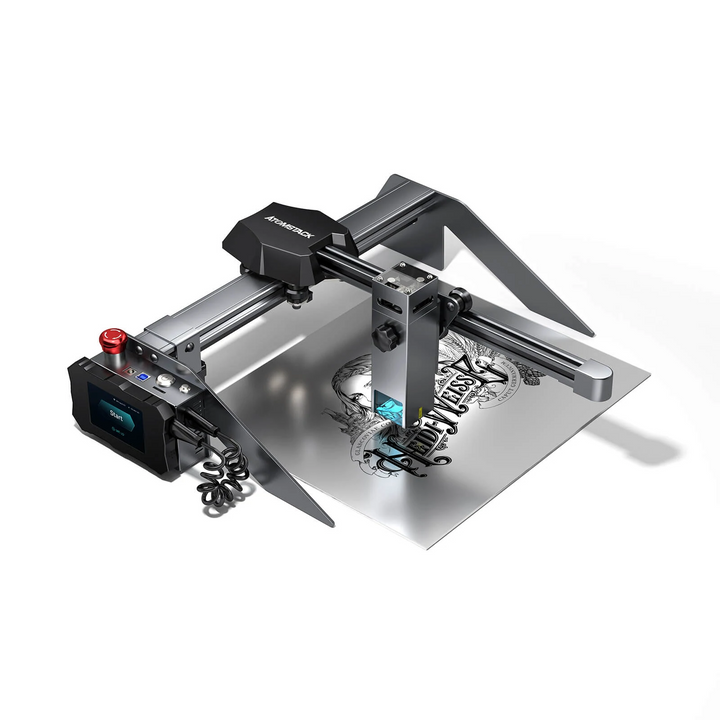

Advantages and Disadvantages of Laser Engraver

Products or works of art may benefit greatly from the personalization that laser engraving equipment can bring. Machines like the Atomstack here can quickly and precisely engrave designs onto a variety of materials, including glass, metal, plastic and wood. However, it is crucial to understand the pros and cons of using these devices before investing in them.

Advantages of laser engraving equipment

The main benefit of using a laser engraver is that it is much faster than traditional engraving methods. This translates into the ability to get the job done quickly and accurately. Additionally, laser engravers have a much shorter learning curve compared to other technologies. With some basic training, anyone can easily use a laser engraver. Last but not least, laser engravers are incredibly adaptable, producing excellent results when used on a wide variety of materials.

Disadvantages of laser engraving machine

The main disadvantage of using a laser engraver is expense; depending on the size and power you need; these devices can be quite expensive. There are also certain limitations on the types of materials that lasers can act on. For example, certain metals may not be suitable for such a machine because they absorb too much heat or reflect too much light. Finally, because the laser beam is very powerful, it can seriously injure the material being engraved as well as the operator if used incorrectly. Because of this risk factor, laser machines of any kind should be operated with the utmost caution.

Short life

The relatively short service life of laser engraving equipment is one of its main disadvantages. This is because laser engraving equipment uses a powerful laser to cut and engrave objects, which can wear out the machine over time. Additionally, laser engraving equipment requires frequent maintenance and repairs, which can be expensive.

Material Compatibility Restrictions

Laser engraving equipment can only be used with certain materials, which is another disadvantage. For example, metal or glass cannot be engraved with laser engraving equipment. Also, some lasers can only be used to engrave certain materials, such as plastics. Therefore, it is crucial to know what materials a laser engraver can be used with before making a purchase.

High starting price

Laser engravers are usually quite expensive, which is another disadvantage. Laser engraving equipment can cost anywhere from a few hundred dollars to several thousand dollars, depending on style and features. In order to adapt to the needs of various materials for engraving, many organizations also need to purchase multiple laser engraving machines. Therefore, starting a laser engraving business can be quite expensive.

Specific expertise required

Laser engraving machine operators require special education and training. To avoid damaging the machine or the material being engraved, operators of laser engraving machines must understand how to use them properly. Therefore, before using the laser engraving machine, the company must invest in training employees how to use the laser engraving machine.

Health hazard

Another disadvantage of laser engravers is that using them can be a health hazard for the operator. Prolonged inhalation of toxic gases produced by laser engraving machines can be dangerous. Additionally, the powerful laser light used by this device can damage your eyes if the operator does not follow the necessary safety procedures.

Iin conclusion

Without compromising precision or quality, Atomstack and other laser engravers offer businesses an efficient option for adding a unique design and personal touch to their products or artwork. While these machines have some drawbacks, including cost and safety concerns, their speed and versatility make them an attractive option for many companies looking for a reliable way to get tasks done quickly and correctly, every time. If you're considering buying one of these machines for your company or project needs, make sure you understand its pros and cons.

Previously, when manufacturers had to mark patterns such as barcodes, images or text on surfaces, they had to choose between traditional engraving or screen printing. However, these procedures are costly, impermanent and often damage parts.

However, with the implementation of laser marking, engineers are able to create characters, numbers or images without damaging the part. Instead of using physical tools to etch the surface or transfer ink, the process uses a focused laser to produce damage-free, easy-to-read marks.

Laser marking has become an essential part of manufacturing - helping businesses track their products, improve quality, minimize counterfeiting and more. To help understand the potential behind this technology, we have listed the advantages of laser marking in manufacturing.

The process is clean and environmentally friendly.

Other marking processes, such as inkjet or chemical etching, use ink and chemicals in the marking, which are not only expensive consumables for businesses, but also have a negative impact on the environment. Laser marking, on the other hand, does not use any consumables – the manufacturing process is clean, economical and energy-efficient.

It also eliminates the cost and downtime associated with cleaning, repairing or powering the printer. While labels may peel or become damaged over time, laser marking can provide a permanent identification of a part and eliminate the need to perform it multiple times.

Since the process is contactless, laser marking ensures clean processing and minimizes contamination. The damage-free process involves minimal or no material penetration as the printing system burns through the material through marking.

0 Comments

What kind of laser engraver to engrave metal?

Don't make the mistake of thinking that any laser engraver will work on metal.

Not all laser engravers can cut metal surfaces, and you need to be aware of certain types of engravers.

Fiber-optic laser

If you are looking for a fast and efficient laser engraver, an engraver using a fiber laser engraver can do the job perfectly.

Remarkable performance in speed and ideal for laser engraving even on uncoated metals.

Carbon Dioxide/CO2 Lasers

Thanks to the laser beam, CO2 laser engravers are fast and efficient machines. It can engrave materials such as metal, plastic, stainless steel and even wood.

However, when engraving metal, I recommend choosing a CO2 laser cutter with a laser power over 150 watts.

Important Note: At 150Wh, you are already dealing with an industrial machine. Always follow safety precautions to avoid any accident or injury.

Crystal laser

Most crystal laser cutters are affordable and still get the job done.

The beauty of using crystal laser cutters is that they are light and portable and fit on most desks.

Unfortunately, you need to be careful with the type of metal you engrave. In most cases, crystal laser cutters are only suitable for coated metal surfaces.

Attention Atomstack users, there is some big news for you. On August 20th we launched a new Atomstack R30 IR fiber laser module to complement the previous model.

As you know, diode lasers are great for engraving and cutting wood, but not so good for engraving metal and plastic. Infrared fiber laser modules are especially important if you have a lot of needs in metal engraving.

Some time ago, Atomstack released a M4 laser marking machine, powered by infrared laser, but easy to carry, the working area is only 70*70mm.

It is worth mentioning that the Atomstack R30 infrared laser module is very safe and belongs to the cold light source, which will not cause damage to human skin, and will not produce fireworks during the engraving process.

Let's discuss the parameters of the Atomstack R30 infrared laser module. Its light source is an infrared fiber laser. The wavelength is 1064nm, the spot spacing is 0.03mm, and the pulse energy is 20,000Hz. At the same time, it belongs to the cold light source, which does not hurt the surface of human skin, and does not catch fire when engraving. It is a safe laser. Because it is a cold light source, you can't do anything to reduce the weight, and you can't make a hard reduction.

Applicable models:

S20 Pro, A20 Pro, X20 Pro,

X7 Pro, A10 Pro, S10 Pro, X7

A5 Pro, A5 Pro+

A5 20W, A5 M30, A5 M40,

A5 M50, A5 M50 Pro

P9 M50, P9 M40, P7 M40, P7 M30

Fiber lasers like this offer creators the additional prospect of increasing the efficiency of blue diode lasers and being able to do things they couldn't before. If you're a longtime Atomstack consumer, it's time to improve your gear and let those dense metals vibrate.

0 Comments

Top Laser Engraved Gifts for Someone Special

Laser engraved gifts give you unlimited opportunities and potential. Laser engraving can elevate an ordinary gift to something extraordinary as it can become a marker of a special occasion. It can tell the closest people in your life that they matter and that you want this gift to be something they can cherish forever. Below we take a look at some of the best gift ideas that can be laser engraved for those special people and moments in your life.

Charcuterie board

The perfect gift for any occasion is a custom charcuterie board. Whether inviting friends for a big game, needing to amp up your weekly game night, looking to add a little something extra to your book club, or wanting to celebrate a special anniversary, laser engraved deli boards are fun and Unique options.

One can also create a centerpiece in their kitchen that can be passed down to the next great chef in your family. These boards also make a great wedding gift and can be paired with a meat and cheese basket for a second mini honeymoon for newlyweds. An engraved deli plate is a memorable gift that makes a statement and always tells a story when friends enjoy a delicious meal.

Custom knife

From multi-tools to buck knives to chef knives, your customers will be able to show that special someone they really care about with a thoughtful custom laser engraved knife. This is a versatile gift for Mr. or Mrs. Fix-It because any situation can be easily resolved with a personalized multi-tool.

For the outdoorsy types, a personalized buck knife is a must have tool for camping. If any of your clients are hunters or fishermen this is a great option for them as they need it at all times. A personalized buck knife will be a gift that lasts and will be the talk of the town for a long time.

Every great chef has a beautiful and reliable chef's knife in their arsenal, so your clients will be able to tell the chef in their life they care with the ultimate laser engraved gift. Such a knife will become something they see and use every day, making it a thoughtful and beautiful gift to add to a chef's collection.

Wine glass

A gift for any occasion, laser engraved wine glasses are one of the most versatile items people can give to someone they care about. Birthdays, weddings, anniversaries, or celebrating company milestones are all ideal gifts, and a laser engraved wine glass will be a lasting reminder of memorable and special moments.

Custom wine glasses also provide a fun way to mark and commemorate small, special events, such as a weekend getaway with friends or keepsakes from an extraordinary party. It's a great way to tell eventgoers that their presence counts, and every time they salute with a laser-engraved wine glass, the memories made will live on.

Photo frame

Laser engraved photo frames can be the perfect container for your clients' most cherished memories such as graduations, birthdays, weddings, vacations and the many great times in their lives.

A personalized photo frame is the perfect gift for those we have a close relationship with as it means we will create more memories together in the future. Allow your clients to gift those closest to them in their lives, allowing them to display thousands of words of memories.

0 Comments

How to choose a laser cutting machine?

Laser cutters come in many shapes, sizes, flavors and prices. As for the latter, you can spend anywhere from a few hundred to a few thousand dollars. Therefore, choosing the right machine for your hobby or business needs is absolutely crucial. There are three main types of consumer lasers—diode, CO2, and fiber optic.

A good laser cutter will be one that can consistently produce precise and high-quality cuts on many different materials. This pretty much rules out any possibility of using a diode laser, since while more affordable and easier to maintain and transport, diode lasers don't pack that much punch; they tend to be better engravers than cutters for most materials division. If all you have is paper, cardboard, fabric, etc., then a diode laser might be all you need.

Fiber lasers would be great, but these lasers are very expensive kits that are well out of the reach of the average consumer. That leaves us with CO2 lasers: a pleasant middle ground when it comes to the three main laser types. CO2 lasers are much more powerful than diode lasers, and the price doesn't always go up that much.

As a workshop machine, it can be difficult to find a CO2 laser cutter that fits the studio space. It is important to know where you are going to place your laser cutter and how it will get to its designated location. It may need to be taken apart and put back together, a lengthy process that includes realigning mirrors and aligning lasers.

Safety is absolutely paramount for any laser cutter. Laser cutters can be extremely dangerous machines and should be handled with extreme care. Laser cutting generates a lot of heat, often on flammable objects. Many laser cutters incorporate safety technologies designed to reduce accidents. Air assist prevents small fires from breaking out, and emergency stops and auto shutoffs are perfect for this type of machine.

Then there's the usability factor. Thanks to smart software and compatibility with control methods, some laser cutters make the workflow incredibly easy. Good software is key to the user experience of these machines, and without it, they can be very difficult to master. LightBurn is an excellent choice for many laser engravers and cutters, it's not particularly expensive, and it has a relatively shallow learning curve.

The Atomstack A5 Pro is Atomstack's entry-level laser engraving and cutting machine - a device that attempts to strike the sweet spot between affordability, ease of use, and functionality. For the most part, it's fine, and its looks and user-friendliness are undeniably excellent in its execution.

How profitable is personalization with lasers?

A pen with a name. Wine glass with custom engraving. Company logo on promotional items. Engraved nameplate. Simple, everyday objects become unique with laser personalization.

Earn handsome profits with laser orders. The sale price of a personalized product can be 5 to 10 times higher than the sale price of a standard product without personalization. Personalize with laser engraving to cost-effectively turn single pieces, small batches and large batches into one-of-a-kind pieces.

Custom engraving is guaranteed to create priceless and lasting memories. Our team is dedicated to creating high quality products and gifts that you will be proud to own and share with friends and family. It truly showcases our passion for graphic design and laser engraving. We make sure that every client is taken care of and 100% understands their unique perspective on engravers. Our engravers, designers and woodworkers are professionals in their art and combine to create the perfect custom engraving experience.

The world's first 33W laser power output laser engraver S30 Pro. The latest 6*6W laser coupling technology can cut 20mm wood board, 10mm black acrylic board and even 0.1mm stainless steel board at one time. The high-density laser can easily cut 25mm thick wood and 30mm thick black acrylic for multiple operations, and can directly engrave mirror stainless steel, ceramics, opaque glass and other materials.

0 Comments

Top Wood Laser Engravers and Cutters 2023

For precise engraving, marking and cutting of wood and wood composite materials, a wood laser cutter is an excellent tool. If you have a high-quality wood laser engraver, you can personalize almost everything. Wood laser cutting machines are becoming more and more popular these days. Not only product designers and small business owners need it, but also individuals who want to decorate their homes with their artwork.

The wood laser engraving market can be difficult to decipher, and there are tons of wood laser cutting machines to choose from. So, choosing the best wood laser cutter can be difficult if you don't know where to start. But worry no more about that, as this article contains a comprehensive guide to the best laser wood engravers available, with options for every price and purpose.

There are both high-quality and substandard woodworking routers on the market. Some products suck, but some are better than others. The question is, which products are high quality and which are not. Buying the best wood router is one of the most frequently asked questions.

The Atomstack A5 Pro is a powerful and adaptable laser engraver that brings industrial-grade technology into your home. The machine was developed for all types of users, from hobbyists to experts. The output power of the CNC laser engraving machine is 5.5W. Ultra-fine laser focus area down to 0.23 mm2. Not only can it engrave, but it can also cut 1/2 wood and acrylic; no need to change focus while engraving, and the new laser can perform high-energy cutting and precision engraving at the same time. Fixed-focus lasers are more stable in power than zoom lasers.

It offers new eye protection features. Protect your eyes perfectly with the protective shield of the laser engraver, which can block 95% of ultraviolet rays. If you are not wearing your glasses, you and those around you may see the laser engraving. Reduce the price of glasses and the hassle of wearing them.

Accurate scale marks on the X and Y axes make it easy to make quick length measurements. The large engraving interval of 410x400mm can meet a wide range of engraving needs.

The machine is compatible with a variety of mature engraving applications, including LaserGRBL and LightBurn, and supports Windows XP/7/8/10 (LaserGRBL) and Mac systems (LightBurn). Supported engraving file formats include NC, BMP, JPG, PNG, DXF, etc.

The machine uses a built-in screw instead of a combined coupling. The stepper motor is integrated with the screw rod to make the laser movement more precise and the coupling more durable.

Wood Laser Engraving Machine Frequently Asked Questions

Above, we mentioned the top-ranked wood laser engravers and cutters. A atomstack laser engraver and cutter is an excellent tool that can be used for a variety of different projects.

Wood Laser Engraving Machine Frequently Asked Questions

Above, we mentioned the top wood laser engravers and cutters. A laser engraver and cutter is an excellent tool that can be used for a variety of different projects.

What wood can you laser engrave?

Laser engraving works best on light woods that are not prone to staining. Many types of wood can be laser engraved, including Adler, plywood, Douglas fir, cork, and balsa.

How to Choose the Best Type of Wood for Laser Engraving

All woods have different compositions that affect how they interact with the laser beam. When choosing the right wood for your project, it is crucial to consider the color of the wood. Darker woods often have laser-etched markings that are harder to see. In contrast, lighter woods will produce a deep, dark burn when etched, resulting in more clearly defined marks. By taking the time to consider the color of your wood, you can ensure your final project has the best possible detail and visibility.

An important aspect is to check the resin content. Resin is a sticky solid organic substance found mainly in plants. When the electromagnetic laser beam hits the wood surface, the resinous polymer is burned first, followed by the rest of the wood tissue. In this case, wood with a higher resin density will burn darker, while wood with a lower resin content will burn lighter. A simple design with contrasting colors is more professional than a darker or more elaborate design. Therefore, it is crucial to check the resin content of the wood you choose.

Another key factor to consider is choosing wood with the fewest streaks. Wood Streaking generally makes the wood more reflective and resistant to attack by external bacteria. In most cases, lumber producers will scratch the wood before selling it, as doing so will make the wood more durable. In this case, it is crucial to consider the wood streaks before laser printing.

Also, it is highly recommended to choose a lighter wood for higher design quality. In contrast to darker woods, lighter woods allow for more pronounced and high-quality layouts. In this case, the base color of the wood will remain similar to its original color. As a result, dark subjects create dark burns when engraving wood surfaces, and patterned text is difficult to read. Also, photos on engraved surfaces will be blurry and unprofessional. In contrast, lighter woods will produce a darker and darker burn during etching, giving you clear marks for maximum visibility.

Finally, when laser engraving wood, it is crucial to choose the best type of wood possible. While most woods are technically suitable for laser engraving, some are better suited than others. Most laser engravers consider alder, cherry, basswood, balsa, veneer, plywood, and maple to be the best woods for laser engraving.

https://www.atom-stack.com/blogs/buyer-guide/what-software-do-you-use-with-atomstack

0 Comments

Best Metal Laser Engraver

Laser engraving is the art of using a powerful beam of light through optical magnification to leave stunning marks on hard surfaces, including ceramics, wood, and metal. The technique involves firing a high-energy beam of light at a targeted area to vaporize material and leave a permanently visible mark. Color changes can also be due to chemical reactions between the material and heat from the laser beam, foaming, charring or ablation.

The type of laser treatment depends on the material. On harder surfaces, such as titanium, the laser beam will ablate the surface. This means removing microscopic debris from the surface. By contrast, the beam burns through soft materials like wood and rubber.

Atomstack A10 Pro

The engraver is sold with five main components, packed in a small box. All the electronics are usually in one enclosure; you just need to unpack and reassemble the frame and connect the wires, power and data cables. Unless you've built a machine before, it takes about 45 minutes to read through the how-to manual and actually set it up. And because every wire and part is unique in design, you can't interchange connections or parts.

The frame and rods are made of high-quality steel, which is resistant to warping.

The machine runs on two quiet stepper motors. One is for the x-axis and the other is for moving the laser head along the y-axis. Focusing guides on the head move it along the Z axis, i.e. up and down according to the thickness of the material.

The A10 has two diode emitters instead of the one we often see in many atomstack laser engravers. The main diode points directly at the material. The other emitter is perpendicular to the main emitter, but as the beam bounces, the composite lens is tilted at a 45 degree angle. This bends the beam through a 90 degree angle, connecting the beam from the main diode. The result is a doubly powerful router.

With a 10W beam illuminating the surface, heat buildup is unavoidable. Luckily, a fan on top of the unit cools the area down.

The engraving machine is compatible with LightBurn and customized LaserBox Basics software, which receives data via USB data cable, Wi-Fi or TF card.

The Atomstack A5 Pro is a standard desktop engraver with a working surface area of approximately 252 square inches, a 5W module and a compression point. The compression spot houses several crystal-clear lenses that compress the coarse, weaker laser beam into a narrower but more intense beam. A more focused laser can easily tear through 0.5" thick wood. If you want a generous work area, the extension kit effortlessly extends the length from 21 inches to 33.5 inches.

In addition, the high-performance lightweight aluminum structure consisting of one-piece lead-screws flexibly forms the guide rail of the laser module. On a smooth pole, the laser module can cover 430 inches per minute. This impressive speed is useful when working on complex designs and time is not on your side.

The UV filtering acrylic on the laser module filters out up to 97% of UV rays making it safe for your eyes and skin. This feature also allows you to have a clear 180 degree view of what the machine is doing from above.

Finally, the Atomstack A5 is compatible with both Mac and Windows operating systems and software. You can use the free LaserGRB software or pay for an advanced design software called LightBurn. After coming up with a unique design, you can convert it to NC, BMP, JPG, PNG or DXF files. The machine has no problem with either of them.

Top choice for creativity: Atomstack laser engraver can engrave a variety of materials such as metal, wood, bamboo, plastic, leather PCB boards, aluminum oxide, lacquered metal, and more. You can make your own carvings according to your preferences, use your imagination

Excellent laser engraving technology: A5 Pro laser cutting machine has 5~5.5w output power, 0.16mm ultra-fine compressed laser focus area, engraving accuracy reaches 0.01mm, making the engraving process more fine, easy to cut wood and acrylic

180° Panoramic Viewing: The UV-resistant acrylic on the laser module can filter 97% of ultraviolet rays, protecting your eyes and the people around you. The specially designed 180° panoramic viewing area allows you to appreciate your work

High-performance structural design: Atomstack A5 40W machine design, integrated screw rod, the fastest running speed can reach 11000/min, more stable and flexible when engraving complex patterns, allowing you to obtain better results more easily.

0 Comments

Laser Cut Design

Craftsmen, designers and creators can use atomstack laser cutting files to cut or etch/engrav designs, shapes, text or patterns on a variety of materials. It also involves cutting these materials into smaller pieces, often assembled into larger handmade objects. Laser cutters are newer in the craft and hobby world but have been around for years in other settings and can add an exciting dimension to your crafting projects.

Laser cutting materials and advantages

While etching and engraving can be used on almost any surface, cutting is limited due to its high mechanical strength. Some of the more commonly used cutting materials include cork, various woods, acrylic, paper, and leather. While the materials used were somewhat limited, the project certainly wasn't! Using a laser SVG file on your laser cutter can essentially replace the process of manually carving out blocks of material to create artwork, a tedious and error-prone task.

However, with the right laser engraver, the process is cleaner and the end product neater. Fine, intricate and repetitive details can also be easily created with an laser engraver. With the right settings, such as power and speed, artisans can produce any design they want in seconds, depending on the complexity of the laser-cut design. There are files specifically for cutting paper or plastic, wood, etc., in every possible pattern and design you can imagine. Be sure to check out our selection of free laser cutting files!

Inspire your creativity with laser cutting

Craftsmen and designers looking to spark their creativity with a laser cutter will definitely want to check out the Atomstack Carved Cork Tripod Tutorial. Don't miss this incredible video that shows you how to carve recipes on a cutting board. For some big food fun, this carving on pumpkin pie tutorial is pretty cool!

If you work in manufacturing and are considering laser cutting for your next project, you may be wondering what the benefits are. Is laser cutting really better than traditional cutting methods like dies, punches and similar tools?

We've compiled a list of several benefits of laser cutting to help you learn more about it and why it's so convenient.

Cutting accuracy and precision

Laser cutting uses a highly compact, high-intensity laser to deliver an incredibly focused beam of light to the material being cut with extreme precision.

In most cases, the intense lasers melt and vaporize materials with unparalleled precision. Plasma cutters, on the other hand, typically have tolerances of around 0.02mm, while some die cutting equipment have tolerances of 1-3mm or more.

Laser-cut wood panels are often the best solution when high precision is required. This is one of the reasons why laser cutting is so common in the aircraft industry where tolerances are very tight.

Short lead times reduce costs by eliminating the need to change or modify tooling.

One of the most notable advantages of laser cutting machines is the cost-effectiveness of laser cutting, especially for small projects. Atomstack a5 m40 laser cutter does not require any special or custom tools to complete your task. It also doesn't have a body cutting surface that would wear out.

All that is needed to make a component or part with a laser cutter is the material to be cut, the laser cutter, and a plan that can be loaded into a computer. Even for low-volume projects, this can result in overall cost savings, especially compared to traditional tooling and fabrication.

Cedar live edge rustic cabins can be made using laser tools that also have fewer mechanical moving parts, reducing maintenance and operating expenses and helping to reduce the cost of using a laser cutting company.

Able to handle jobs of varying complexity

There is no job that a laser cutter can't handle. High powered lasers can work on brittle sections of material where the area being cut has slight bends or deformations.

Laser cutting machines can be used to quickly and efficiently fabricate the most complex geometries and cut them with unrivaled precision and good tolerance levels with correct schematics.

Increase paper utilization and reduce waste

Another advantage of the precision and accuracy of laser cutting is that it can work with a large proportion of the sheet. Atomstack p9 m50 laser cutters can efficiently maximize the number of valuable components and parts in any given sheet of material through nested cuts.

Again, this reduces the overall project cost and speeds up the completion date. Less time is required to change out new material slabs, and less raw material is wasted by machining and cutting operations.

While lasers are generally not suitable for particularly thick metals, with waterjet or plasma cutters preferred, the versatility of laser cutting makes it an important aspect of modern machining.

0 Comments

Laser Engraving Cutting Project Ideas

Have you ever had an idea and wondered what it would look like in reality? The previously unheard of ability to create original compositions based solely on your imagination. However, technological developments are changing this.

Laser cutting involves cutting material using light from electromagnetic radiation - a Atomstack X30 Pro laser cutting machine directs a high-power output laser light onto the material through optics. Laser cutting projects can have an industrial status and are also introduced into school systems, micro factories and art lovers.

The possibilities are endless for what you can build with a laser cutter. Here are some ideas.

Laser Cutter Project Ideas

A wide range of products can be designed using a laser engraver cutter, from jewelry and artwork to coasters and timepieces. Here are some concepts you can try.

Laser Cut Business Cards

Business cards are not a new concept, but laser cutting takes them to the next level. In addition to laminated paper, businesses can also use laser-cut wood to give their business cards a premium look. For many businesses, business cards are a way of introducing your business to new customers, and making a good first impression is essential to stand out in the market. Combining the best of laser cutting and woodworking - you can brand your card by engraving your company name or logo.

Key chain

Key chains are more useful than many of us realize; not only do they make our keys stand out, but they also make them easier to find. However, for most of us, keychains are cheap plastic items we get for free or as souvenirs. But what if you could cut out your own key chain and create the design of your dreams?

Using a laser cutter, you can create themed key chains, such as a festive Christmas tree, or your one-of-a-kind special key chain that will serve as a keepsake for years to come.

Best Portable Metal Laser Engraver

A laser engraver that delivers high-quality performance without taking up too much space – the Atomstack P9 M50 laser engraver is an outstanding piece of equipment. From rough cuts to fine details - it can handle a wide range of designs.

What we like about this product:

As you probably know, it can be difficult to find a laser engraver that can serve multiple purposes without being too heavy. Therefore, we recommend the P9 M50 laser engraver. It only weighs 8 lbs. The dimensions of the machine are 19.3″ x 10.6″ x 5.1″.

This is a atomstack laser engraver working on a diode laser module that combines laser focusing and spot compression. It is compatible with LaserGRBL and LightBurn. You can operate it both online and offline. You'll also love its 11000 mm/min speed.

You'll also appreciate the 3.5-inch touchscreen feature, which provides a user-friendly interface. It has a protective cover that filters UV rays. A movement accuracy of 0.01 mm and a repeat position accuracy of 0.02 mm make it also ideal for handling a wide variety of materials.

Advantage:

Lightweight and portable laser engraving machine

Ideal for all skill levels

Impressive Accuracy and Speed

Panoramic filter glass for eye protection

Rugged aluminum body

Shortcoming:

Tricky assembly process for beginners

Time-consuming software setup process

0 Comments

How to start a small business in atomstack?

Rapid advances in technology in the laser industry have opened doors of opportunity for many users. The continuous development of laser cutting and engraving machines has gradually improved the quality and quantity of engraved products on the market today.

In fact, many create an additional source of income by starting a laser engraving business. This relatively new field already exists, with engraving companies already popping up in garage workshops, home craft rooms, mom-and-pop shops and even industrial settings.

Come to think of it, some of the products you use every day have passed through the workbench of a laser engraver or cutter. Cutting boards, coffee cups, home improvement and other products have encountered laser engraving machines or cutting machines in the production process.

If you are looking for a business that is easy to learn, quick to learn and reasonably profitable in the long term, then you should consider starting a laser engraving business. Anyone who owns a diode laser engraving machine, works hard to learn the necessary skills and has the right work ethic can make a lot of money from laser engraving.

If you manage to capture the imagination of consumers, your small business will continue to grow.

So, what is atomstack s10 pro laser engraving and cutting?

Laser cutters use powerful, ultra-thin laser beams to etch, engrave or cut materials. You can use a focused laser beam to burn, melt or vaporize images or letters into various objects to create designs and patterns. This is an automated, non-contact manufacturing process based on heat, so it is accurate and low risk. These machines allow you to create complex parts with or without custom-designed tools.

This process applies to a variety of businesses, including sculpture, fashion, arts and crafts, and merchandise. We'll dive into the product options available to you later.

Is a Laser Engraving Business Profitable?

A laser engraving business can be very lucrative as long as you are willing to work hard and pass due process. Like any business, the laser engraving industry doesn't give money. You need to do market research, find out what is needed in your area, and work on creating a brand that connects with your target market.

Fortunately, laser engraved products are great for manufacturing and selling for a number of reasons, starting with the low overhead associated with laser processing. atomstack s20 pro laser engravers are the biggest investment, and with recent market changes, you can get high-powered lasers for a fraction of the cost of the past. You need to spend a little money on equipment, build a website and promote your name there, but it doesn't have to be expensive.

Many people think of trophies and gifts when they think of laser marking or engraving, and while they can make money, if profit margins are a priority, you'd better think bigger. Getting bulk orders from corporate or industrial laser engraving customers is where the big money is made, and we'll talk more about that later.

The Benefits of Starting a Laser Engraving Business

Profit: The beauty of a laser engraver is that you can turn a bland or ordinary object into something custom. Personalization is one of the biggest consumer trends right now, and atomstack a5 pro+ laser engravers can take advantage of this directly. What's more, you can use a simple material like acrylic but turn it into something special that people are willing to pay dearly for.

Speed: One of the reasons laser engravers are so profitable is that you can quickly create custom products. Laser technology allows you to add designs to surfaces in seconds, much faster than any traditional hand engraver.

Accuracy: Laser technology is special because it is so accurate. The smaller the laser beam, the more detailed and clear your designs will be, and the more you can charge per unit.

Environmentally friendly: There are no chemical elements in your laser engraving machine and no limited resources such as ink are used. As long as you take good care of your machine, it can last for years without much maintenance.

Overhead: A laser engraver is a one-time cost with a small investment, and once it's up and running, you can quickly pay for it. They usually don't require much in the way of replacing parts and can last for years. As a laser engraver, you can break even quickly, which is one of the reasons it has such an attractive prospect.

Convenience: Not only should your atomstack laser machine come with a detailed manual, but the best manufacturers make sure they have top-notch support and a curated online support community so you can get answers to any questions you have.

0 Comments

The Best Wood Laser Engravers of 2022

Buying a laser engraver for your woodworking project can be overwhelming. This is especially true when there are so many machines to choose from.

First, there are different types of laser engravers, each of which will produce different results. More worryingly, not all of them are suitable for carving wood. So you may end up with the wrong machine.

Can a laser engraver engrave wood?

Yes, a laser engraver can engrave wood and do it easily. Of all the available options like Chisel, Dremel and Cricut Maker, laser engravers arguably produce the best results faster.

But in the end, the results will depend on the laser engraver and the type of wood you use. There are three main types of laser engravers to choose from.

CO2 lasers, also known as gas lasers, use carbon dioxide gas to generate a laser beam. When an electric current is passed through the gas, it emits a laser light with a wavelength of 10,000 nanometers.

This wavelength is most suitable for treating non-metallic surfaces such as leather and wood, as well as plastics.

Fiber lasers are the most powerful lasers, producing a wavelength of 1064 nanometers. These machines have the smallest focal point and can be 100 times more intense than CO2 lasers.

While fiber laser machines are popular, they are not the best for wood carving. They are designed for engraving objects with harder surfaces such as metal.

As the name suggests, UV lasers emit UV light from 10 nanometers to 400 nanometers. The wavelengths are much shorter and don't generate as much heat. Therefore, processing with UV laser is also called cold working.

These lasers are just as good at engraving materials like wood as CO2 lasers and are best for marking and even micro-marking.

So if you were to ask, "What laser can engrave wood?" the answer is all lasers, but a CO2 laser engraver is the best choice.

In addition to the above, another type of laser engraving machine is also gaining popularity. That's a diode laser. These are smaller in size and cheaper. Therefore, many laser engravers designed for home use are using diode lasers.

The next factor to consider is the type of wood. While you can laser engrave on almost any wood species, the results will vary. To choose the best wood block for your project, check the following:

Streaks - Streaks are dark stains on wooden surfaces with varying mineral content. While stripes look good on wood, they are not suitable for carving. Therefore, you need to choose the wood with the fewest streaks.

Resin/Sap Content - Ideally, the wood should have a high resin or sap content. Logs with higher resin content will produce deeper burns, while logs with lower resin content will produce shallower cuts.

Tint - Logs should be lighter in tint as they will produce darker burn marks. It's much more difficult to etch designs on dark wood and get similar results.

Some wood species that meet these criteria are alder, cherry, basswood, hard maple, and balsa. I always enjoy carving other people out of these logs.

Atomstack S20 Pro

This powerful yet affordable machine meets all the requirements of a reliable wood laser engraver. It has sufficient optical power, large working area, ultra-fine focal length, and easy operation.

0 Comments

A5 Pro Laser Engraving Machine Review

The Atomstack A5 Pro is a home assembly laser engraver like no other. First, the price of the laser engraver A5 Pro is higher than most other home build kits, followed by quality and power. Whether engraving or cutting 8mm layers, the precision and quality are excellent.

The open extruded aluminum frame design of the laser engraver A5 Pro and other self-build engravers is common among DIY hobbyist machines because they are easy to build and maintain. Protective goggles must be worn, and good ventilation is essential, which also limits where they can be used.

However, this laser engraver A5 Pro is very powerful and it is worth noting that Atomstack invested in high quality parts and a solid design for this machine.

It takes about an hour to assemble, but you might be able to put it together faster with a little concentration. The instructions show you how the machine is assembled, but some areas are a little hard to understand.

The point is to put the belt on the pulley; this requires loosening and tightening the seat belt. While this works for one axle, the other requires removing the pulley, putting it in the belt, and reinstalling the pulley. Likewise, cable guides require careful positioning. Put them in the wrong place and you need to backtrack the build to correct it.

Once all the pieces are put together, the design is very clean and there is no room for parts to be installed incorrectly - everything fits snugly with no gaps in the joints. That's fine, but it does make initial assembly quite tedious, though not to the point of being impossible.

Once built, it is ready to be tested with laserGRBL for PC or LightBurn for all other systems.

The Atomstack A5 Pro may be a build-your-own laser engraver, but it's still incredibly capable.

First, it features a 410 x 400mm work area, and the frame's open design allows you to slide large materials through in stages, up to 450mm wide.

A standout feature is the 10W laser output, which, along with compressed spot technology, enables the A5 Pro to cut 8mm layers at a time. The power of the laser is so high that it can also engrave hard surfaces such as stainless steel.

When you use the A5 Pro, the ultra-fine engraving accuracy of 0.01mm makes the engraving and cutting quality stand out. This precision enables high-quality image transfer to the material.

Due to the precision of the laser, the Atomstack uses a powerful autofocus design for the machine. The material height is adjusted manually via the big red knob on top of the laser, and the machine handles the fine-tuning. This alone can save a lot of time and improve the overall quality of your prints.

One feature of laser engravers that often annoys us is the need to be plugged into a computer all the time. It's nice to see a machine with an ESP32-DOWD-V3 chip and a 32-bit microprocessor built in to handle the files internally, so it doesn't need to be connected all the time.

A few professional safety features take this laser engraver to the next level. There's a large emergency stop button and a flame detector that activates if the material catches fire rather than being engraved or cut. Another safety feature is the internal gyroscope, which automatically activates the kill switch if the machine is tilted 15º or more.

Once the image, vector or cut files are loaded into the software and adjusted, they can be sent to the machine. The initial connection is simple, with the usual manual adjustments to material, initial position and laser height.

Once everything is adjusted, the power can be set and the engraver turned off. The power and precision of this laser engraver is immediately apparent. The initial engraving showed a high degree of detail, and the engraving was fast and precise.

As we've found with other self-build machines, it's important to make sure everything is nice and tight, the machine has good rigidity, and that the belts are tensioned before starting.

Upon closer inspection, the quality of the engraving is as good as that of Glowforge(Opens in a new tab). The only problem is that being an open design, the smell means you need to be in a well ventilated room and you need to wear protective glasses.

This is the first laser engraver we've seen to successfully cut thicker materials. In this test, we passed the 6mm layer without issue, producing nice clean edge lines.

Overall, for engraving and cutting, the Atomstack A5 Pro does an excellent job; our only concern is that there is no case for a machine of this power.

The build of some parts of this laser engraver tested me with the initial build, trying to get the belt to fit on the pulley and small screws into the aluminum extrusion. It's not hard, just tedious, the key is moving from the tight space of the kitchen table to the expansive space of the workshop.

Once built, the construction is solid, far exceeding what we've experienced with other laser engravers of this size. All these anodized parts are also more aesthetically pleasing.

It's all relatively easy to set up, though connecting to Wi-Fi via the iOS app or the machine is a little trickier. We also found that while there was a lot of information in the printed manual, we couldn't always follow some of the finer prints.

The Atomstack A5 Pro works very well, the structure is excellent, the attention to detail paid off in the quality and accuracy of the engraving and cutting.

The bottom line is that there is no case or extractor, but other than that, the machine is pretty much faultless.

The A5 Pro is the leader in the field, and while it's more expensive than other laser engravers, it's not a leap to make it unaffordable. The A5 Pro expandable is also a great option, with an attachment point on the tool head for an air pump to help extract some smoke and extra attachments that allow you to cut round objects like bottles.

The Atomstack A5 Pro is one of the best laser engravers we've seen, especially considering the price. If you're looking for a professional-grade laser engraver at an affordable price, the A5 Pro is the machine. Atomstack Laser Engraver will be your best choice!

Popular Searches: Laser Engraver for Wood, Laser Engraver for Metal, Laser Engraver for Acrylic, Laser Engraver for Leather, Laser Engraver for Glass,

0 Comments

Laser Cut Acrylic Plexiglass

There's no denying that working with some laser-cut materials is a lot of fun for both novice and experienced cutters. Our laser cutting experts at Vector & Raster agree that acrylic is one of the most satisfying materials in and out of the studio. The flame polished edges created during the acrylic laser cutting process look great, just flip your design over and you can choose a glossy or matte finish for your laser cut acrylic parts in the Pastel range over make acrylic a use A wide range of materials for a variety of production jobs.

Custom Laser Cut Acrylic Production

Acrylic, also known as plexiglass, is a thick plastic that can be produced with glossy finish, matte finish, mirror finish, glitter finish and many other amazing effects. We usually use acrylic sheets of different thicknesses, available anywhere from 1mm to 10mm thick.

The large number of acrylic sheets used by our laser cutting experts at Vector & Raster are typically around 3mm thick as they are available in a wide range of colours and finishes, including burst pastels that can be used to create attractive and eye-catching signs, in countless other commercial or consumer products.

Using laser cutting technology to cut larger acrylic sheets, our laser cutting experts are able to create high quality acrylic signs, 3 dimensional 2 dimensional signs, and provide our customers with a final product that looks good in the end.

In today's blog post, we'll take a closer look at acrylic's potential for producing a variety of laser-cut products, including corporate signage or logos, and consumer products. So, without further ado, let's take a look at one of our latest projects involving laser cut acrylic in one of our favorite pastel colors.

Our Custom Laser Cut Acrylic Projects

For this particular project, the client attempted to create a series of whimsical designs for custom products, inspired by a selection of beloved Pokemon, which was a lot of fun for our laser cutting technicians. The plexiglass used to complete this project is pale yellow and 3mm thick. Customers choose to use the matte finish of acrylic on their smooth surface, so our laser cutting experts make sure the acrylic is flipped over to its preferred side to ensure the finished product is to the customer's liking.

Using precision cutting and engraving techniques, our laser cutting technicians are able to produce clear designs with all the details needed to meet customer specifications.

These atomstack laser-cut acrylic panels are also finished to ensure high-quality flame-polished edges so the final product looks smooth from any angle and catches light when viewed from the side. The ability of this acrylic part to work with natural or artificial light also makes acrylic signage more visible than alternative laser-cut materials like wood or paper.

As you can see in the photo of one of the laser cut panels of the final product, the results of this project really speak for themselves. Both our laser cutting specialists and the client are very pleased with the results of this project, and the client may produce acrylic products in many other designs.

What can laser cut acrylic be used for?

In addition to being a valuable material for the production of laser-cut signs, laser-cut acrylic can be used in a wide range of other commercial and consumer products, including jewelry, accessories like earrings, ornaments like Christmas tree ornaments, and even cards or anything else you'd like to see Wedding invitations that stand the test of time.

The flexibility to choose a glossy or matte finish makes laser-cut acrylic a very popular material for makers of fancy jewelry or small boutiques looking to expand their original wares. Laser engraving directly on acrylic is also a very popular method for adding text or designs to logos or signage as well as smaller consumer products such as jewelry.

Essentially, laser cut acrylic is a versatile laser cut material that small business owners, independent manufacturers and large corporations can use to produce higher quality products and even as signage for their business premises, detail or decoration.

Why Laser Cut Acrylic with Vector & Raster?

With over 20 years of experience producing custom templates, designs and countless other laser cutting products for a range of independent and corporate clients, our laser cutting experts can bring your wildest project ideas to life. Our studio spaces are packed with rafters with laser cutting tools and techniques and an abundance of high quality laser cut materials to ensure all their finished products shine right at the source.

But of course it's not just tools that make a good carpenter. All of our laser cutting experts have all the right industry knowledge and experience to deliver the best possible finished product at the end of every project they undertake.

https://www.atom-stack.com/pages/laser-for-engraving-wood

https://www.atom-stack.com/pages/best-laser-for-wood-engraving

0 Comments

How to Prepare Your Image for Laser Engraving

If you've never used a laser engraver before, you might be surprised at what can happen when you finally get into the workshop and start your own machining process. Laser engraving is a versatile application - it can be used to mark medical equipment or aftermarket auto parts that can withstand the harshest conditions, or to commemorate a birthday or special event by marking the date on a souvenir.

One of the coolest applications for atomstack laser engravers we've seen is working with photorealistic photos and images. Our galvo laser systems are so precise that in addition to engraving words and phrases, you can actually engrave photorealistic images into stainless steel. You have to be comfortable with grayscale, but when you get your images set up correctly, this incredible process produces great results.

Based on our own trial and error process, we have come up with the ideal step-by-step process for preparing your chosen laser engraving image. With so many different types of laser engravers available, and so many software options for preparing images, it's hard to generalize about a one-size-fits-all approach, but we've done our best to make this guide accessible to everyone. Whether you're an experienced designer working with Corel DRAW or the free online tool GIMP, follow these steps to prepare your images for sculpting.

Step 1 - Start with a high-quality image

When choosing an image for laser engraving, it is important to start with a high-resolution, high-quality image. A stamp image scanned from an old photo album will not retain its sharpness through the transformation that occurs before the image is ready for engraving, and you will not be able to "inflate" or "zoom in" like a picture from a CSI TV show. Make sure to use it well camera to take high-resolution photos for the best results.

Step 2 - Cut to Perfection

The advantage of starting with a high-quality photo is that you can effectively crop it and make it look bad. Cut out the parts of the image that you don't want, and resize the rest to the size you want it to appear on the stainless steel or other material you're using.

Step 3 - Remove the Background

This step is important and may require using the clipping tool in your image processing software or some handy Photoshop skills. If you don't remove the background, your image may get lost in the background during the engraving process. By making the background of the image pure white and the laser engraving only the object in focus, you can avoid obscuring objects with irrelevant background details you don't want.

Step 4 - Convert the Image to Grayscale

Laser engraving naturally produces grayscale images by cutting different lines at different depths for different number of passes. Generating an image in grayscale gives you a good idea of what it will look like when sculpted onto the material of your choice - your image is almost ready! Looking at the grayscale image should help you with the next steps, you'll have to make some slight edits to the image for best results.

Step 5 - Edit your photo however you choose

Now that we're working on something similar to what a laser engraver will produce, we can start making any version that's important to achieve the desired result. Editing photos is a highly subjective process, but we'll offer some advice. These can be applied to photos of people, places or objects.

You want to try to maximize contrast in key areas of your photo. This usually means making whites whiter and dark areas darker.

Areas that appear white in real life, such as eyes or nails, should be highlighted in the image by reducing any shadows that appear there. Set the black to 3-6% to help these areas stand out better.

Remove shadows from any faces in the image, as the dark contrasts too strongly with hair, which is usually darker. Set black to 10-15% for best results.

For dark tresses, darken them. For lighter tresses, you can make them lighter.

Step 5 Alternative - Color Index

If you're not going to edit your photos, there's an option you can choose to help maximize contrast without having to make any complicated changes yourself - that tool is Color Index. If you plan to use color indexing, you may need to do this before changing the image to grayscale.

A color index is a tool that some imaging software has that repaints your photo with a fixed number of colors for maximum contrast. It essentially looks at all the colors in the image, combines them into any number of groups of your choice, and replaces each group with one color. All you need to do is choose the number of colors you want for the image and let the image processor do the rest.

Step 6 - Sharpen Your Image

Sharpening just makes lines look thicker, and it's a simple tool that exists in almost every photo editing program. For photos of people, sharpen the eyelashes, lips, hair around the face, and any other areas you want to emphasize in the final sculpted image. If you photographed objects or buildings, focus on the most important lines that add texture to the image and give it a three-dimensional feel.

Step 7 - Convert and Export

Your image should now look the way you want it to be sculpted on stainless steel, plywood, or other materials. The next step is to convert this image to a bitmap of the appropriate resolution and transfer it to laser CAD software for engraving. When exporting as a bitmap, the recommended resolution is approximately 200 pixels per centimeter. This ensures that your images are displayed in high resolution on the material of your choice.

Step 8 - Press the red button

The last and most fun step is always setting the options on the laser cutter and pressing "start" at the end after all the hard work is done. Engraving differs from laser etching in that it makes deeper cuts in the material, and it's usually better to program the laser to make multiple passes over the material, rather than trying to blast a large piece of steel or wood in a single pass. Our galvo lasers use an oscillating mirror system to cut at extremely high speeds, so your project will be complete in minutes.

in conclusion

Just follow these simple steps and you can reproduce images of stunning quality on a piece of stainless steel, birch or laminate. You also don't have to be a graphical wizard -- in fact, it doesn't matter what program you use, as long as it performs the basic functions we've outlined above. Whatever you choose, the most important thing to remember is to start with a clear, high-resolution image. A great picture is a great starting point for creating great creations with our laser engravers.

0 Comments

Prevent Burning and Scorching When Laser Cutting

One of the skills required for CO2 laser engraver and cutters is to try to avoid scorch marks on the edges of the engraving. For some materials, burn marks are unavoidable no matter where the laser's focus is. However, by using the correct substrate and following the directions carefully, you can minimize time-consuming cleanup during the cutting process.

In this article, we'll tell you what types of wood to avoid, and provide helpful tips on using lasers to cut wood without burning it.

What causes burn stains on cut wood?

The first thing to understand is that the laser beam never actually touches the surface of the wood. Just like inside a chimney, soot from the combustion of organic matter can deposit in the surrounding area. So there's no need to worry about laser damage to wood; it's just one example of taking precautions to avoid soiling woodworkers.

There are several ways to avoid these stains, the most popular is to apply tape to the wood surface. You can also modify laser cutter settings, apply coatings, use atomstack air assist—and make sure to choose the right wood, preferably one with a high moisture content.

Choose your wood carefully

Certain types of wood are better suited for laser cutting than others, mainly because of the amount of binder used to make certain wood materials. Laser cutters tend to work best on softer woods with simple grain patterns, such as alder and basswood.

Materials like plywood and MDF are more challenging due to their high glue content - but if you do need to use them, you always have the option of using tape, coating or sanding.

Softwoods: Softwoods such as balsa and alder require a low power setting and can be easily cut without too much resistance. Using lighter wood results in minimal contrast between the original surface and the newly cut edge.

Hardwoods: Hardwoods like cherry and oak are more likely to scorch than balsa because you need to use a stronger laser to engrave or cut the surface. The result of this is darker edges and a higher chance of burning.

Veneer: Veneer lumber uses wood as a surface material, so it works well for carving in many cases. It may not be suitable for laser cutting, depending on what the core material is.

Plywood: Plywood is one of the more difficult substrates to cut without burning, although it is possible if you use our tips below. It is one of the most versatile materials and comes in many sizes and styles. However, you'll want to choose one that's designed for laser cutting, such as birch plywood.

wavelength

Even the wavelength of the laser can affect the cutting edge of the material and a 1.06 micron fiber laser is not recommended. Conversely, 9.3 or 10.6 micron fiber bundles produced the fewest burn marks when cutting wood with a CO2 laser.

Resin content

The sap or resin content in the wood can make a huge difference when using a atomstack s10 pro laser cutter. Materials with a high resin content like alder are more prone to charring or have dark edges, while oak has a lower resin content and is better for a bright, clean cut.

test before starting

The type of wood you choose and even the thickness of a particular wood can have a big impact on your finished product. Speed, power, wattage and your environment also play a critical role. Therefore, we recommend that you always do a material test on offcuts before starting.

5 Tips for Preventing Burns When Laser Cutting

With a little patience and practice in the initial stages, there are some simple solutions to prevent burn marks from CO2 lasers.

1. Use transfer tape on the wood surface

You can apply masking tape to wood surfaces, but application tape comes in ready-made wide rolls that work perfectly with atomstack a5 pro laser engravers. You can apply tape to both sides of the product for a perfect clean. Use a small plastic spatula to firmly press down on the tape, making sure there are no air bubbles that could interfere with the cutting process.

The main disadvantage of this strategy is that it is time-consuming to apply the tape and then remove it. To make money with a laser cutter, speed is paramount—removing tape piece by piece can seriously impact productivity. Don't worry though - you can choose to use a plastic razor to effectively remove the tape.

2. Modify CO2 laser power settings

There are several settings you can use to avoid burning. Once you find a setting that works for each wood, you can jot it down to speed up the process in the future. The focus of the laser can be manually adjusted to make it slightly smaller. A slightly diffused laser reduces the amount of smoke produced while still providing enough energy to engrave or cut your material.

0 Comments

What is color laser marking?

Color laser marking, also known as color laser engraving, refers to adding color to the marking. "Mark" is the technical term for it. Color laser marking can mark materials with a variety of pigments. This technology has indeed been invented for 10 years. At first, it was first used in metalwork and jewelry. Manufacturers use color for laser marking or engraving. This makes their products more diverse and beautiful.

The advantages of color laser marking compared with ordinary marking machines

Color laser marking machine is one of the standard marking machines. The color laser marking machine adds other colors to the ordinary marking machine. Traditional conventional marking machines are gradually being replaced by laser color marking in various places. Color marking of stainless steel can be achieved by process annealing. Laser color markers can provide greater precision, speed and flexibility.

1. More colors

Color laser marking machine can mark more colors. This is the most significant advantage of color laser marking machine compared with ordinary laser marking machine. Color laser marking machines mainly use the latest digital technology. Use a laser beam to react on the surface of a metal or other material. Say goodbye to the monochrome era of laser marking! Laser marking is no longer monotonous!

Several material types for color laser marking.

1. Plastic

Plastic is a very frequently used material. Currently, color laser marking machines are also commonly used to hold plastics. Plastics can show color contrast with a color marker machine. This can make ordinary plastic appear different colors. For example, the red plastic marked by a color laser marker cannot be changed to another color later. Plastics produced in this way can be colorful.

2. Metal

Engraving metal by color laser marking machine is its most commonly used function. Especially the atomstack color laser marking machine marks on stainless steel. This is very popular in industrial applications. It can produce different colors on metal surfaces through different frequencies, speeds or focal lengths. Therefore, the color laser marking machine can make the untreated metal surface have richer colors.

Application of Color Laser Engraving

The application range of laser color marking machine is also very wide. It can also do the work that ordinary marking machines can do. And on the basis of the conventional marking machine, the scope of application has been expanded.

Jewelry: jewelry such as bracelets, pearls, etc., can add more beauty.

Nameplates: More Artistic and Unique

What are the effects of color laser marking during use?

(1) The working environment of the color laser engraving machine should be good, and the power supply voltage should be stable. If the voltage fluctuation is too large, a regulated power supply should be configured. The placement of the machine should pay attention to skills, and it cannot work in an environment with obvious vibration and humidity, because the speed and power of the color laser engraving machine will affect whether the color meets the standard. In this case, the marking color engraved on the engraved surface of the material will be more pure. The laser current cannot be too large, it must be below 20mA, and it must be as deep and fast as possible. Make sure the engraving is accurate enough.

(2) The laser tube is a heating body, and the quality and quantity of the circulating water must be guaranteed: quality - to ensure that it is clean and free of debris. The circulating water will be changed regularly (two days). The water must be changed when the machine is not working; volume - ensure sufficient circulating water (above 20Kg), and ensure that the circulating water temperature is 5-25 °C.

(3) In the case of meeting the functional requirements, the optimal working method is adopted to prolong the service life of the laser tube as much as possible. For example, try to use cutting programs.

atomstack a10 pro , atomstack s20 pro

Machines for Color Laser Engraving

1.Hispeed MOPA fiber laser marking machine

MOPA fiber laser marking machine uses a laser beam to scratch the surface of various substances. MOPA laser markers can draw in black and white on most metals and plastics, black on anodized aluminum, and color on stainless steel and titanium. The marking function exposes the underlying material by evaporating the surface material, thereby engraving exquisite patterns, logos and text. Also, this laser marking machine can be used for gorgeous patterns like serial numbers, barcodes, etc.

0 Comments

7 Tips for Buying a Laser Engraver

1. Focus on the core application: laser engraving or laser cutting

It's easy to be drawn to how many other applications a machine can perform. A good generalist is a compromise machine in almost every way. Just because a machine can cut and engrave doesn't mean it can do both functions well. A purpose-designed machine will always perform the core application better, so it's no surprise that laser cutters cut better than laser engravers, and vice versa.

2. Throughput is almost always the key to business success.

Even if your business volume is low right now, production speed is critical. Higher throughput will provide the opportunity to reduce selling prices while increasing your profits and you can also deliver faster. These three elements are the keys to being competitive, winning and growing your laser engraving business.

3. Carefully consider the true cost of ownership, as this can have a huge impact on profit erosion.